TA INSTRUMENTS DMA Q800

Sample Requirements

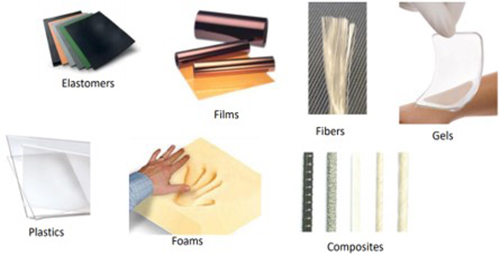

Single and Dual Cantilever: Evaluation of cure and all purpose

- Sample size

- Single: 17.5 mm L, up to 15 mm W and 5 mm T

- Dual: 35 mm L, up to 15 mm W and 5 mm T

3- Point bend (for medium to high modulus)

- Small: 20 mm W and 10 mm T

- Large: 50 mm L and 10 mm

Tension

Films: 8- 20 mm L, 5- 6.5 mm W and up to 2 mm T

Shear sandwich

Shear deformation of gels, viscous resins and adhesives: 10mm x 10 mm square of up to 4 mm thick

Compression

Low-medium modulus (foams), 15- or 40-mm diameter and up to 10 mm thick

Summary of Technique

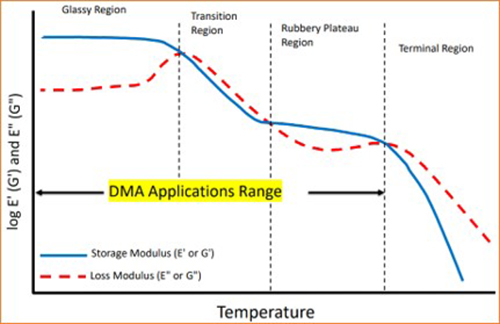

A Dynamic Mechanical Analyzer (DMA) measures the mechanical/rheological properties of a material as a function of time, frequency, temperature, stress and strain. DMA works on the principle of applying a force or a deformation to a sample, then sample’s response, which will be a deformation, or a force is measured .

Information Provided & Detection Limits

Composition

Degree of crosslinking, comparison of crystallinity levels, molecular orientation, effect of a filler.

Viscoelastic Properties

Storage modulus, loss modulus, Tan delta, glass transition temperature (Tg), sub-Tg molecular motions (beta and gamma relaxations.)

Physical Properties

Prediction of impact resistance, testing of creep or cold flow, cure behavior.

Lifetime Predictions Using Time Temperature Super Positioning

- Minimum Force 0.0001 N and Maximum 18N.

- Force Resolution 0.00001 N

- Modulus Precision ± 1% and Temperature Range -150 to 600°C

- Frequency Range 0.01 to 200 Hz

- Heating Rate 0.1 to 20 °C/min

- Dynamic Sample Deformation Range ± 0.5 to 10 000 µm

Contact Information

Location: Thermal Analysis, Rheology, and Polymer Processing Lab

Point of Contact: Dennis Ndaya

dennis.ndaya@uconn.edu

860-486-4075