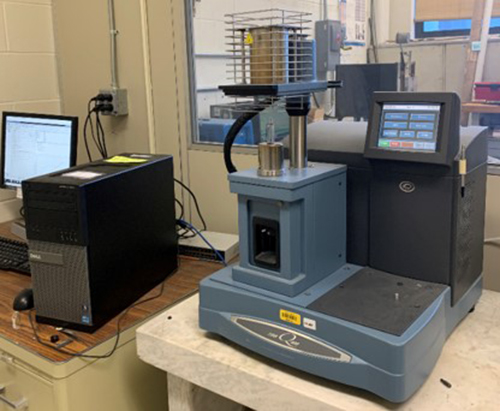

TA INSTRUMENTS TMA Q400

Sample Requirements

Maximum Sample Size

- Solid: 26 mm (L) x 10 mm (D)

- Film/fiber: 26 mm (L) x 0.5 mm (T) x 4.7 mm (W)

Summary of Technique

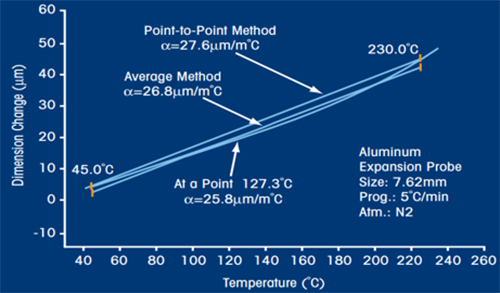

- TMA measures the dimensional changes of a sample as a function of temperature or time while it is subjected to defined mechanical stress or load under conditions of controlled force and atmosphere.

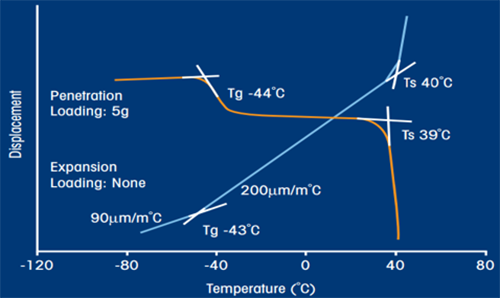

- The modes of measurements includes Compression, Expansion, Penetration, Tension and 3-Point Bending

Information Provided & Detection Limits

- Dimensional Changes

- Expansion coefficient

- Expansion and Shrinkage

- Softening

- Young’s modulus

- Sensitive Tg information as compared with DSC

- Foaming and Swelling characteristics

- Creep behavior

- Phase transitions Curing

- Thermal stability (oxidation, decomposition, delamination)

Detection Limits

- Temperature Range (max): -80 to 1,000°C

- Temperature Precision + /- 1°C

- Measurement Precision +/- 0.1 %

-Sensitivity 15 nm and Frequency 0.01 to 2 Hz

-Force Range 0.001 to 1 N and Resolution 0.001 N

Lab Location and Contact Information

Location: Thermal Analysis, Rheology, and Polymer Processing Lab

Point of Contact: Dennis Ndaya

dennis.ndaya@uconn.edu

860-486-4075