Research

Polymer Program Researchers Kelly Burke and Anson Ma Receive CT Regenerative Medicine Grant

By: Kelly A. Salzo

Kelly Burke (Peter Morenus/UConn Photo)The CT Regenerative Medicine Research Fund Advisory Committee has awarded Dr. Kelly A. Burke (IMS/CBE) and Co-Investigator Anson W. K. Ma (IMS/CBE) a seed grant titled “Human intestine tissue model by 3D printing”. The grant will provide $200,000 for the research endeavor involving chemically modified silk proteins to be used for 3D printing, which will subsequently form stable hydrodels. These materials will be printed into intestine-like crypt structures and will incorporate cells from human intestine to improve understanding on how the geometry of the system alters the function of the cells. Dr. Burke is hopeful that “the data generated will not only advance our efforts in 3D printing soft materials, but will also enhance understanding of how cells interact and undergo repair processes in cultures with geometries that are more representative of the human intestine.” The applications of this research will be important to the study of intestine tissue models, which may be used to investigate disease progression and to develop therapeutics.

Anson Ma (Peter Morenus/UConn Photo)Dr. Kelly A. Burke received her Ph.D. in Macromolecular Science and Engineering from Case Western Reserve University in 2010. In 2014, she joined UConn as an assistant professor in the Chemical and Biomolecular Engineering Department and is a member of the IMS Polymer Program. Her research interests include synthesis and structure-property relationships of multifunctional polymeric materials, stimuli responsive polymers and networks, natural and synthetic biomaterials, and the design and application of polymeric systems to modulate inflammation and promote healing.

Dr. Anson W. K. received his Ph.D. in chemical engineering from the University of Cambridge in 2009. He joined UConn in 2011 as an assistant professor in the Chemical and Biomolecular Engineering Department and the IMS Polymer Program. As Principal Investigator for the Complex Fluids Laboratory, his research centers on understanding the complex flow behavior (rheology) and processing of various complex fluids including foams, emulsions, nanoparticle suspensions, and biological fluids.

IMS Researcher Anson Ma Receives 2015 Metzner Early Career Award

By: Kelly A. Salzo

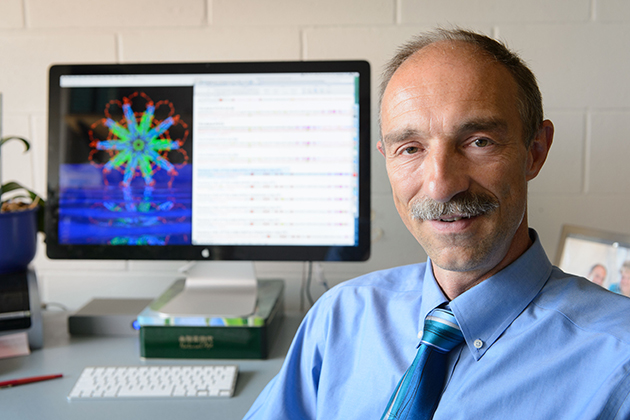

Assistant Professor Anson W. K. Ma (IMS/CBE)Anson W. K. Ma (IMS/CBE), Assistant Professor in the Department of Chemical and Biomolecular Engineering, will receive the 2015 Arthur B. Metzner Early Career Award. This distinguished award, named after rheology pioneer Arthur B. Metzner, is distributed annually by the Society of Rheology to a young researcher “who has distinguished him/herself in rheological research, rheological practice, or service to rheology.” Dr. Ma will deliver a plenary lecture at the upcoming 87th Society of Rheology Annual Meeting in Baltimore, where he will receive a plaque and a $7,500 honorarium.

Anson W. K. Ma received his Ph.D. in Chemical Engineering from the University of Cambridge in 2009. He joined UConn in 2011 as a member of both the IMS Polymer Program and the Chemical Engineering Program. As Principal Investigator of the Complex Fluids Laboratory, his research focuses on understanding the complex flow behavior (rheology) and processing of various complex fluids including foams, emulsions, nanoparticle suspensions, and biological fluids. His lab is developing new techniques to improve the reliability and push the existing resolution limit of inkjet and 3D printing technology. Dr. Ma’s research on 3D printing has recently been featured on the front page of the Chronicle newspaper and Channel 8 News. In 2012, Dr. Ma received TA Instrument’s Distinguished Young Rheologist Award, which recognizes product innovation and research of new materials and applications that expand the field of rheology. The following year he received a prestigious NSF CAREER Award for his research on exploiting the size and shape of particles to improve the stability of emulsions typically found in agricultural, pharmaceutical, and personal care products. More recently, Dr. Ma is leading a major effort to establish a center of excellence for additive manufacturing of soft materials at UConn. The mission is to accelerate technology transfers to the industry and to provide an important training ground for future workforce in advanced manufacturing.

Douglas Adamson Joins TRI Board of Directors

By: Kelly A. Salzo

Dr. Douglas Adamson, (IMS/CHEM) Associate Professor in the Chemistry Department, has just been appointed to the board of directors of TRI/Princeton. Dr. Adamson joins a team dedicated to TRI’s mission of promoting the advancement of science and the enhancement of innovation, while pursuing potential contributions to society. The board of director’s diverse scientific disciplines allow for an interdisciplinary approach to surface science, materials science, optical measurement, and fluid/pore interaction. Doug becomes the only academic member of the board, with other members being senior scientists from companies such as DuPont, Johnson & Johnson, and Procter and Gamble.

TRI/Princeton is divided into a variety of laboratories and centers dedicated to serving industry, government, and academia. In addition to research, TRI’s Professional Education Program offers a variety of conferences, workshops and courses to provide its members with the tools to accommodate industry’s ever-changing needs. As their website explains, “We remain vigilant in seeking new opportunities and discoveries that will sustain the Institute into the future while remaining true to our principle of inspiring, educating and connecting through science.”

Graduate Student Feature: Garrett Kraft

By: Kelly A. Salzo

“One of the things I really like about working in the polymer industry is that you can make a material that is tangible and has unique properties which make it different from any other material that’s out there,” Garrett explains. “This creates the opportunity to construct high performance materials for very specific applications.”

IMS graduate student Garrett Kraft realized his passion for polymer science while pursuing his bachelor’s degree in chemistry at the University of Wisconsin. After receiving his degree, Garrett sought out schools with strong polymer science programs and UConn’s prestigious Polymer Program caught his eye.

During his three years at in the IMS Polymer Program, Garrett has worked on a number of research projects under the direction of Dr. Douglas Adamson, which include developing adhesives that selectively bind particles in a complex mixture, investigating the use of synthetic non-peptide based polymers to mimic the catalytic activity of proteins, and exploring the applications of two-dimensional materials in polymer composites. He is also currently working on a project with ExxonMobil, creating polymers with a very narrow polydispersity and complex architectures.

Garrett attributes his current success in the field to being open to change. The materials science industry is in constant flux due to innovations in technology, which is one of the aspects of materials science he finds most compelling. “Research is always evolving and you are always finding new skills to develop,” Garrett says. He also finds his communication skills crucial to his success in the lab, as well as his constant curiosity.

In the future, Garrett is interested in pursuing green technology, specifically deriving or isolating monomers from biological feedstocks and creating materials which can break down naturally. Finite petroleum resources and environmental concerns make this area of research very appealing to polymer scientists.

Besides conducting graduate research, Garrett serves as president of the UConn Society of Plastics Engineers (SPE) student chapter. Under Garrett’s direction, the UConn chapter recently applied for official status as a student chapter and since then, the student chapter garnered support from the National chapter, including a visit from the CEO and financial support. Very recently, the organization received national recognition and has been awarded the Outstanding Student Chapter Award which Garrett will receive at the ANTEC conference in Orlando, Florida at the end of the month. Garrett also spearheaded the initiative to make UConn’s chapter more engaging for its members by organizing plant tours and research seminars. “We have also been trying to connect more with alumni,” Garrett explains. “Two previous alumni came in and gave us insight on what they are doing currently, what exactly happens after grad school, and how the job searching process works so students can see what they can do with their degree.”

When asked what advice he would give to other students pursuing a career in material science, Garrett says: “Always keep on exploring. Try to find more information about areas you are interested in by talking to different people, whether they are students, faculty, or people in industry. Hopefully by talking to different people, you discover something you find fascinating enough to research for your Ph.D.”

UConn Scientists Featured in C&EN for Graphene Foam Research

The Polymer Program of the Institute of Materials Science was recently mentioned in Chemical & Engineering News (C&EN), a weekly magazine published by the American Chemical Society, for research concerning graphene foam materials. The article highlights the work of polymer chemist Dr. Douglas H. Adamson (IMS/CHEM), polymer physicist Dr. Andrey Dobrynin (IMS/PHYS), and graduate student Steven J Woltornist (IMS/CHEM), and their revolutionary approach to creating new materials based on the strong attraction of pristine (not oxidized) graphene to high-energy oil and water interfaces. In the past, graphene’s applications have been severely limited due to its insolubility in water and other common organic solvents. To fix this problem, researchers had either relied on chemically altered graphene, which is expensive and ultimately has inferior properties, or extensive mechanical treatments that led to tearing the graphene sheets apart. Instead of viewing graphene’s insolubility as a limitation, the team exploited it by using it to stabilize the high-energy interfaces found in water in oil emulsions. Overlapping pristine graphene sheets at the water/oil interface lead to a local thermodynamic minimum, resulting in stable water in oil emulsions with the water droplets lined with thin layers of graphene. Using a monomer with dissolved initiator as the oil phase, leads to the formation of polymer in the continuous phase, after gentle heating. When the water is removed, a rigid foam remains, which is strong, conductive, and light-weight. These foams and can be used as building materials, ultracapacitor electrodes, conductive catalyst supports, and filters.

Andrey DobryninDr. Douglas Adamson joined UConn in August 2008 as an Associate Professor in the Polymer Program and received his Ph.D. from the University of Southern California in 1991. His research focuses on polymer synthesis for use in self-assembly as well as using graphene and other two-dimensional sheet like materials for composites.

Dr. Andrey Dobrynin joined UConn in 2001, earned his Ph.D. from the Moscow Institute of Physics and Technology in 1991 and is a professor in the Polymer Program. His research focuses on computational approaches to polymeric materials and polymer based nanocomposites.

Steven J Woltornist joined UConn in January 2012 as a teaching assistant for general chemistry, while pursuing a Ph.D. in polymer chemistry. In May 2013, he joined the Adamson research group. His research specializes in the discovery and development of graphene-based materials.

Dr. Anson Ma Featured in Channel 8 Story on 3D Printing

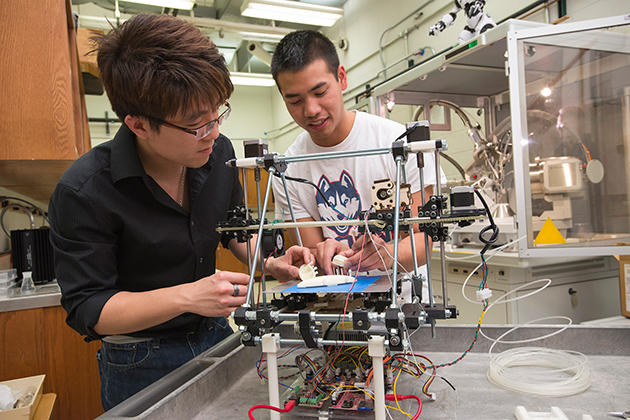

A Channel 8 science story about 3D printing called upon the expertise of UConn’s Dr. Anson Ma to explain some of the current and potential benefits of the technology.

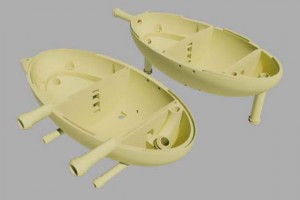

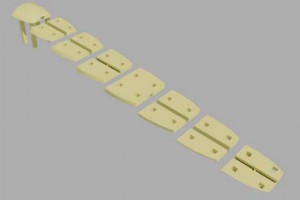

Dr. Ma had challenged his students to create an artificial kidney using 3D technology and they produced it using 3D printing.

“Right now this is a prototype,” said Ma. “The longer term goal is can we incorporate cells, for example stem cells from the patients, then we can create fully compatible organs.”

The story highlights UConn’s commitment to new and emerging technologies as well as the ever-growing importance of materials science.

UConn Researcher’s Nanoparticle Key to New Malaria Vaccine

By Colin Poitras, UConn Today, September 3, 2014

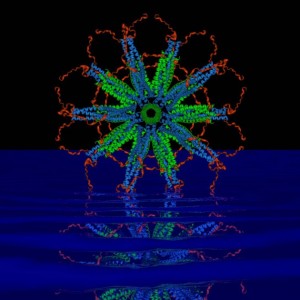

A self-assembling nanoparticle designed by a UConn professor is the key component of a potent new malaria vaccine that is showing promise in early tests.

For years, scientists trying to develop a malaria vaccine have been stymied by the malaria parasite’s ability to transform itself and “hide” in the liver and red blood cells of an infected person to avoid detection by the immune system.

But a novel protein nanoparticle developed by Peter Burkhard, a professor in the Department of Molecular & Cell Biology, in collaboration with David Lanar, an infectious disease specialist with the Walter Reed Army Institute of Research, has shown to be effective at getting the immune system to attack the most lethal species of malaria parasite, Plasmodium falciparum, after it enters the body and before it has a chance to hide and aggressively spread.

The key to the vaccine’s success lies in the nanoparticle’s perfect icosahedral symmetry (think of the pattern on a soccer ball) and ability to carry on its surface up to 60 copies of the parasite’s protein. The proteins are arranged in a dense, carefully constructed cluster that the immune system perceives as a threat, prompting it to release large amounts of antibodies that can attack and kill the parasite.

In tests with mice, the vaccine was 90-100 percent effective in eradicating the Plasmodium falciparum parasite and maintaining long-term immunity over 15 months. That success rate is considerably higher than the reported success rate for RTS,S, the world’s most advanced malaria vaccine candidate currently undergoing phase 3 clinical trials, which is the last stage of testing before licensing.

“Both vaccines are similar, it’s just that the density of the RTS,S protein displays is much lower than ours,” says Burkhard. “The homogeneity of our vaccine is much higher, which produces a stronger immune system response. That is why we are confident that ours will be an improvement.

“Every single protein chain that forms our particle displays one of the pathogen’s protein molecules that are recognized by the immune system,” adds Burkhard, an expert in structural biology affiliated with UConn’s Institute of Materials Science. “With RTS,S, only about 14 percent of the vaccine’s protein is from the malaria parasite. We are able to achieve our high density because of the design of the nanoparticle, which we control.”

The research was published in Malaria Journal in 2013.

The search for a malaria vaccine is one of the most important research projects in global public health. The disease is commonly transported through the bites of nighttime mosquitoes. Those infected suffer from severe fevers, chills, and a flu-like illness. In severe cases, malaria causes seizures, severe anemia, respiratory distress, and kidney failure. Each year, more than 200 million cases of malaria are reported worldwide. The World Health Organization estimated that 627,000 people died from malaria in 2012, many of them children living in sub-Saharan Africa.

It took the researchers more than 10 years to finalize the precise assembly of the nanoparticle as the critical carrier of the vaccine and find the right parts of the malaria protein to trigger an effective immune response. The research was further complicated by the fact that the malaria parasite that impacts mice used in lab tests is structurally different from the one infecting humans.

The scientists used a creative approach to get around the problem.

“Testing the vaccine’s efficacy was difficult because the parasite that causes malaria in humans only grows in humans,” Lanar says. “But we developed a little trick. We took a mouse malaria parasite and put in its DNA a piece of DNA from the human malaria parasite that we wanted our vaccine to attack. That allowed us to conduct inexpensive mouse studies to test the vaccine before going to expensive human trials.”

The pair’s research has been supported by a $2 million grant from the National Institutes of Health and $2 million from the U.S. Military Infectious Disease Research Program. A request for an additional $7 million in funding from the U.S. Army to conduct the next phase of vaccine development, including manufacturing and human trials, is pending.

“We are on schedule to manufacture the vaccine for human use early next year,” says Lanar. “It will take about six months to finish quality control and toxicology studies on the final product and get permission from the FDA to do human trials.”

Lanar says the team hopes to begin early testing in humans in 2016 and, if the results are promising, field trials in malaria endemic areas will follow in 2017. The required field trial testing could last five years or more before the vaccine is available for licensure and public use, Lanar says.

Martin Edlund, CEO of Malaria No More, a New York-based nonprofit focused on fighting deaths from malaria, says, “This research presents a promising new approach to developing a malaria vaccine. Innovative work such as what’s being done at the University of Connecticut puts us closer than we’ve ever been to ending one of the world’s oldest, costliest, and deadliest diseases.”

A Switzerland-based company, Alpha-O-Peptides, founded by Burkhard, holds the patent on the self-assembling nanoparticle used in the malaria vaccine. Burkhard is also exploring other potential uses for the nanoparticle, including a vaccine that will fight animal flu and one that will help people with nicotine addiction. Professor Mazhar Khan from UConn’s Department of Pathobiology is collaborating with Burkhard on the animal flu vaccine.

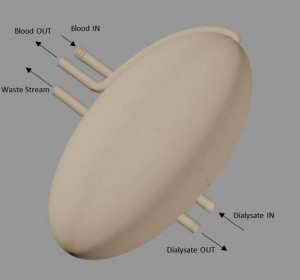

Students Design Artificial Kidney with 3-D Printing

By Rob Chudzik, UCONN Today

Interior components of the 3-D artificial kidney, rendered using AutoCAD software.